PRODUCTS

Wrap Strench Film

Category:

Wrap Strench Film

Size:

36 in. * 200 ft.,48 in. * 200 ft.,36 in. * 500 ft.,48 in. * 500 ft.,36 in. * 600 ft.,48 in. * 600 ft.

Inquiry

Product Description

Stetch film is cost-effective, offers superior protection and is adaptable to fit many load applications. In addition to load stability, Stretchfilm offers protection from dust, debris and moisture. It is also used for securing packages and bundling applications. There are a variety of widths, thicknesses, types and even colours, each of which can be tailored for a range of different scenarios.

STRETCH FILM RESULTS

- Maximises your equipment's stretch potential and provides excellent yield.

- High stress retention maintains holding grip on load.

- Withstands puncture of protruding separator boards & irregularly shaped loads, accepts cuts & snags without zippering.

- Prevents sticking & damage to film of tightly arranged pallets.

- Possible to secure the wrap without adhesive, heat or tape, even at high stretch levels.

- Greater elongation results in higher yield per kilo & the lowest cost per pallet wrapped.

Hand Stretch Film vs Machine Stretch Film

Hand Stretch Film

In a low-volume operation, pallet stretch wrap applied manually is a great solution. Hand stretch film is much lighter and easier to wield than machine stretch wrap. It’s still very effective for securing items on a pallet, especially in the hands of someone aware of the proper hand stretch wrap technique.

Use Hand Stretch Wrap When:

- Pallets are too unstable to transport to a stretch wrapper

- Operational set-up does not support wrapping in specific locations

- Variability in package integrity is acceptable to the customer

- Limited warehouse space

- Low pallet volume

Hand Stretch Wrap Maneuver:

- Hand stretch wrap can provide excellent package stability with the correct technique. Follow these steps for the best results:

- Tie stretch wrap to the pallet (preferably in a corner) to secure.

- Create a foundation by walking around the pallet three or more times overlapping the wrap over both the pallet and the load. Make sure the stretch wrap covers the pallet corners.

- Work your way up the load making sure to overlap each previous layer by 50%. Pull the stretch wrap taut as you go – it’s meant to be stretched!

- At the top of the load, angle the stretch wrap in a way that it pulls the load down towards its center and base. This will minimize the chance of the load shifting in transit.

- Now, work your way back down the load overlapping each previous layer by 50%.

- Re-wrap the foundation at least two more times once you get to that point.

- The stretch wrap will stick to itself. To secure it, cut it from the roll and press it firmly against a previous layer.

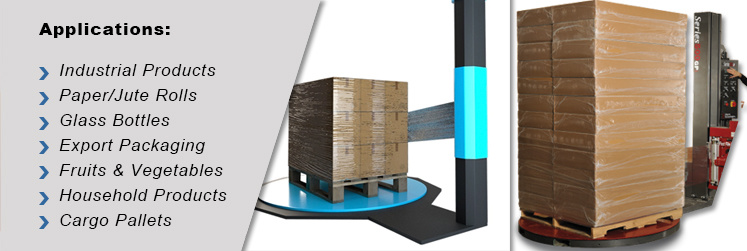

Machine Stretch Film

To achieve maximum consistency, speed and stability in palletization processes, combine automated systems with machine stretch film. When combined with a stretch wrapping machine, machine wrap stretch film is applied to the load using the specific parameters set by the operator for consistent results load after load. Load retention is improved thanks to application optimization.

Machine Stretch Film Advantages:

- Excellent load stability

- Increased film utilization through high pre-stretch

- Consistent performance

- Speed of application

- Integrates with automated palletization systems

Machine Stretch Film Sizing:

- Weight: 25-60 pounds

- Length: 3,000 – 11,000 feet

- Gauge: >=10micron

- Width: 50cm –100cm

Related Products

Inquiry